TTM Has Deep Expertise and Capabilities to Offer Leading-Edge Solutions for Innovative Industrial Applications

One-Stop Solution, Full Lifecycle Support

Global leaders in industrial and instrumentation markets trust TTM for ultra quick-turn and quick-turn offerings that ramp seamlessly to volume. Our dedicated field applications and production engineers can help get your prototype production-ready. We do validation and testing early on to ensure your ramp to volume is easy to achieve, saving you time to market.

TTM can accommodate various needs for medium and high-volume manufacturing through our global footprint of printed circuit board fabrication facilities, R&D centers, and a global team of field applications engineers. We provide differentiated solutions at any point in the product lifecycle. We can offer more options to ensure our customers are fully supported every step of the way.

TTM supports industrial & instrumentation applications at facilities in North America and Asia. We offer multi-site solutions and have material stocking strategies to mitigate risk for our customers, no matter what macro-economic factors come into play. TTM subscribes to several quality management certification bodies and strict environmental, health, and safety protocols to ensure we're leading the industry as a trusted supplier and an excellent employer.

Broad Technology Solutions Offerings

TTM takes pride in our continuous development of solutions that meet our customers' needs. From HDI to rigid-flex to RF components and substrate-like PCBs, TTM has a suite of advanced technologies to bring the most innovative electronics applications to life. TTM's differentiated capabilities make us a strategic partner for teams looking for an advantage in an increasingly competitive marketplace.

Advanced Technology Printed Circuit Boards ("PCB"s)

- Laser microvias

- High-Density Interconnect ("HDI")

- Via-In-Pad-Plated-Over ("VIPPO")

- Flex, Rigid-Flex

- High layer count

- Large format

- Hybrid materials

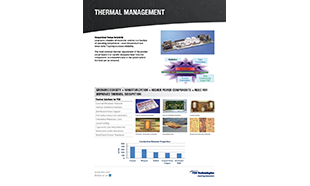

Thermal Management Solutions

Heavy Copper

Thermal management is essential to maintaining component temperature within designed values by removing excess generated heat.

Thermal Vias

Thermal dissipation has dramatically increased due to higher frequencies, increased data rates, and high current required by inverters and motor drives used in solar applications. Compounded by increased component density, all require advanced thermal management techniques to provide reliable products and extended product life.

Find more thermal management solutions in our Solutions section.

RF/Microwave Expertise & Capabilities

TTM has an array of off-the-shelf and custom solutions to enable mm-Wave-reliant applications. We have vigorously tested industry-leading solutions for diverse end markets. We recommend you visit our RF and Specialty Components pages in the Solutions section for complete details.

Related Resources